October 28, 2010 feature

Scientists demonstrate more efficient way to connect nanoparticles for single-electron devices

(PhysOrg.com) -- By connecting single nano-objects together, scientists can fabricate tiny solid-state devices through which a precisely controlled single-electron current can flow. In the past several years, scientists have been developing different methods for connecting single nano-objects, such as metallic nanoparticles, semiconducting nanocrystals, and molecules. However, as the size of the nano-objects decreases, the efficiency of these methods also decreases, so that most methods result in a low yield at the scale of a few nanometers. In a new study, scientists have developed a new way to connect single nano-objects that could overcome these challenges and enable the creation of new nanodevices.

The researchers, Anne Bernard-Mantel from CNRS and the Universite Paris-Sud in Palaiseau, France, and coauthors have published their study on the new high-yield method of connecting single nano-objects in a recent issue of Nanotechnology. In addition to the increased efficiency at small scales, the new method is also compatible with a more diverse range of materials, such as highly oxygen-sensitive ferromagnetic materials. In contrast, previous methods could not use these metals due to their susceptibility to oxidation problems.

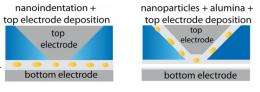

In their study, the scientists demonstrated two similar fabrication processes. Both processes start with a bottom electrode and thin layer of alumina. In the first process, an assembly of nanoparticles is deposited, followed by another thin layer of alumina, and then a resist layer. Using a nanoindentation technique, the scientists drilled a nanohole into the resist layer and then filled it with metal to form the top electrode. The bottom of the nanohole comes to an extremely sharp point that connects with only one nanoparticle. In the second process, the only difference is that the alumina assembly is deposited after the resist layer.

The final result is a solid-state device consisting of an assembly of nanoparticles, while only one nanoparticle is connected to both the top and bottom electrodes. The scientists demonstrated the processes with nanoparticles as small as 2 nm in diameter. They also used different materials, including metallic and semiconducting nanoparticles, as well as non-magnetic and ferromagnetic electrodes.

In contrast with complex and expensive techniques such as electron beam lithography, the new method offers a simpler, cheaper alternative that also provides a higher yield at very small scales. Because the new method is also compatible with ferromagnetic materials, it could be used for investigating nanospintronics. Other possibilities include fabricating chemically grown nanoparticles and molecular nanomagnets.

“The next step is now to adapt this technology to connect isolated molecular magnets,” coauthor Karim Bouzehouane of CNRS and the Universite Paris-Sud told PhysOrg.com.

More information: A. Bernand-Mantel, et al. “A versatile nanotechnology to connect individual nano-objects for the fabrication of hybrid single-electron devices.” Nanotechnology 21 (2010) 445201 (6pp). DOI:10.1088/0957-4484/21/44/445201

Copyright 2010 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.