Carbon fiber stretches from comet to machine tools

Ultra-light carbon-fibre rods used to stiffen a comet probe's legs are now being harnessed by a German manufacturer to boost the precision and efficiency of their laser cutters.

Right now, the rods in question are on a collision course with a comet – literally.

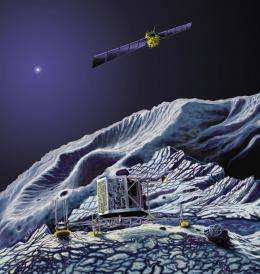

In 2014 ESA’s Rosetta spacecraft will end a decade-long chase through space by catching up with Comet Churyumov–Gerasimenko.

It will orbit the comet and release its Philae lander to anchor itself to the icy surface.

Carbon-fiber rods guarantee safe landing

To ensure a safe landing, the lander’s legs are made of lightweight carbon fiber rods.

Designed by Schutze, a German company in Braunschweig, these rods are six times lighter than steel, but can be made up to 50% stiffer.

These 'sandwich rods' have a lightweight, rigid foam core wrapped in carbon fiber and coated with thin fibreglass.

“No mold is necessary, making the production of tailored rod dimensions feasible,” said director Rainer Schütze. As well as the lander legs, the folding antenna and frame of Rosetta are also based on the lightweight rods.

“The carbon fiber sandwich rods combine high strength and stiffness with very low weight,” added Mr. Schütze.

Thanks to ESA’s Technology Transfer Program, the rods’ special qualities are also improving products here on Earth.

Better cuts and customization

ESA’s technology broker MST Aerospace in Germany put Mr Schütze in touch with Trumpf Sachsen, a German machine tool manufacturer.

“Probably the cooperation would not have taken place without MST making the connection,” explained Mr. Schütze.

Trumpf was looking for ways to improve laser cutting machines that make extremely precise, extremely complex shapes out of large sheets of metal. One common use is for electric motors, which can stack hundreds of thin metal sheets together.

Rather than building a stamping die for the specified shape, Trumpf’s laser machine can precisely cut each panel to fit, then start immediately on an entirely new shape.

“When you do it right, it’s a very, very smooth cut,” said Christian Koerber, Head of New Business Development at Trumpf.

The flexible nature of laser cutting opens up the possibility of offering customised solutions – prohibitively difficult, time-consuming and costly with the previous stamping methods.

Inside the machine, two laser cutting heads are fixed to a crossbar that together weigh 620 kg but move extremely quickly. To make the precision cuts needed, the laser beams are required to stop and turn in less than the blink of an eye. There’s no room for error.

“We need to have a precision of a few micrometers,” Mr. Koerber added – a micrometer is smaller than a typical bacterium. “If the machine stops, it needs to stop exactly where we programmed it to.”

Once ESA brought the two companies together, Schütze’s carbon fiber sandwich rods proved an ideal added ingredient to Trumpf laser machines.

By mounting the laser cutting heads on the light but stiff rods, their machines are able to make the exact cuts needed, while accelerating and decelerating quickly.

With ESA’s help, Trumpf should have as much success landing new contracts as the Rosetta mission promises to have landing on a speeding comet deep in space.

Provided by European Space Agency