Microtextured surfacing may help to eradicate the problem of barnacle larvae in the shipping industry

The US Navy estimates that biofouling—the accumulation of unwanted marine organisms, such as barnacles and seaweeds, on the hulls of ships—can reduce a ship’s speed by 10% and increase fuel consumption by 40%. Coating the ship’s hull with biocides can help prevent biofouling, but the chemicals used are often harmful to the environment. An environmentally friendly alternative to biocides is the use of microtextured surfaces to which marine organisms have difficulty latching onto.

William Birch and co-workers at A*STAR’s Institute of Materials Research and Engineering1 have now revealed a mechanism by which microtextured surfaces deter marine organisms. The finding could help to develop new artificial surfaces for preventing biofouling.

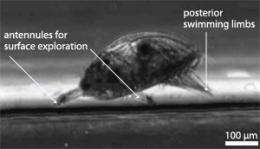

Previous studies have found that barnacle larvae preferentially settle in cracks and depressions because the voids offer better protection from the currents in which they feed. However, the reason why microtextured surfaces reduce barnacle larvae settlement was unclear. For this reason, the researchers constructed an experimental setup which allows them not only to view the exploration behavior of barnacle larvae on different surfaces, but also to study how the size of surface features influences their surface exploration (see image).

To investigate the impact of surface texture on barnacle settlement behavior, Birch and co-workers fabricated polymer surfaces with features of the same size of a larva’s cyprid attachment pad, which is elliptical in shape and about 20 by 30 microns or thousandths of a millimeter. The surfaces were textured with pillars placed 10 microns apart. The columns were five microns and 30 microns high, and 5, 10, 20, 30, 50 and 100 microns in diameter. A smooth surface without pillars was used as a control. Exploration and settling behavior of the larvae were filmed using close-range microscopy.

The researchers found that barnacle larvae were unperturbed by the five-micron high pillars, as their flexible attachment disks could simultaneously flow over and contact the top of the pillar and the bottom of the space between pillars. Thirty-micron high pillars, however, had a dramatic impact on larval behavior. At smaller diameters, the contact area afforded by the tops of the pillars was small, and the larvae found it difficult to attach to the sides of such slim pillars. At diameters of 30 microns or greater, the larvae tended to form attachment points in the cracks between the columns with their disks wrapping around the sides of the column.

“These and other recent findings have spawned a multidisciplinary research program (Innovative Marine Antifouling Solutions for High Value Applications, IMAS), whose objective is to engineer patterned surfaces and measure performance by quantifying their interactions with marine organisms,” says Birch.

More information: Chaw, K. C., et al. Surface exploration of Amphibalanus amphitrite cyprids on microtextured surfaces. Biofouling 27, 413–422 (2011).

Provided by Agency for Science, Technology and Research (A*STAR)