January 30, 2012 report

Scientists rediscover self-healing silicone mechanism from the 1950s

(PhysOrg.com) -- Research in self-healing organic polymers has grown recently, but one simple self-healing mechanism from more than 60 years ago has been nearly forgotten until now. Using this mechanism, which is called “siloxane equilibration,” scientists have demonstrated that silicone rubber that has been cut in half with a razor blade can completely repair itself through heat-activated reversible bonding. The self-healing mechanism could have applications in a variety of areas, such as for designing self-healing surfaces of vehicles and countertops.

The researchers, grad student Peiwen Zheng and Professor Thomas J. McCarthy from the University of Massachusetts, have published a paper on the rediscovery of siloxane equilibration in a recent issue of the Journal of the American Chemical Society.

“We have been working on silicone materials from a couple of different perspectives,” Zheng told PhysOrg.com. “When we rediscovered the forgotten unusual properties of silicones and combined them with today’s research interests, we found that the silicone material with the siloxane equilibration was an obvious candidate for a self-healing material.”

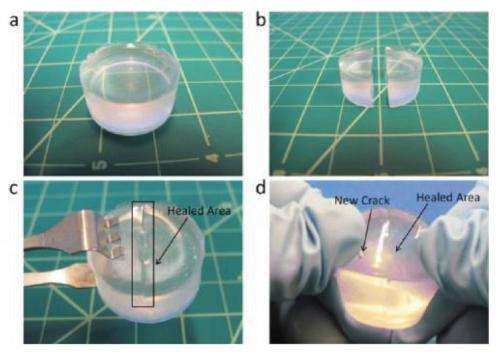

The researchers performed several experiments to test the theoretical predictions from papers published in the early 1950s, as well as to extend some of the experiments performed at that time. In one experiment, Zheng and McCarthy prepared a siloxane-based mixture containing a cross-linking agent and a catalyst. Then they poured the solution into molds of various shapes, such as cylinders, disks, and dog bones. After heating the molds at 90 °C (194 °F) for four hours, the researchers removed clear, rubbery silicone shapes from the molds. The scientists described these silicone samples as “living polymer networks.”

“The silicone network is at a chemically anionic equilibrium,” Zheng explained of the term, “where the reactive center will cleave and reform a covalent siloxane bond.” These bonds are reversible, which enables the two sides of a crack to reconnect under the right conditions.

To demonstrate the self-healing ability, the researchers cut a 1-cm-long cylindrical sample in half using a razor blade. Then they rejoined the two pieces by wrapping them together with Teflon plumbing tape and heating them in an oven at 90 °C (194 °F) for 24 hours. When the researchers retrieved the sample and removed the tape, they found that the silicone cylinder had completely healed. Then they bent the cylinder by hand until it broke again - significantly, it broke in a different location than where it had been cut. The scientists repeated this experiment on different shaped objects with the same results.

In another experiment, the researchers molded a silicone dog bone, which they cut into multiple pieces. Then they rearranged the pieces to fit into a mold of a dog. Heating the sample resulted in a silicone dog with no visible fractures or weak spots where the pieces had been fitted together.

The researchers also quantified the strength of the healed samples in comparison with the original samples using fracture toughness measurements. The data for the two types of samples was indistinguishable, indicating exceptional self-healing.

The researchers explained that, in principle, any cross-linked dimethylsilicone elastomer (only one type was used here) can be converted into a living elastomer by the addition of basic catalysts. This possibility opens up many different routes for synthesizing a variety of self-healing silicione-based materials. While the samples used here required applied heating to self-heal, the researchers predict that samples in a sealed, high-temperature environment would self-heal “autonomically,” or automatically. Zheng explained that self-healing materials, with some improvements, could lead to a variety of applications.

“It can be developed into self-healing coatings on auto vehicles or countertops,” she said. “It is also a ‘plastic’ elastomer which can be used in molding to form desired shapes and patterns. The concept of a self-healing silicone can be used to guide the preparation of elastomers with gradient modulus, Janus elastomers, reversible surface patterns when filled with magnetic particles, and super tough materials which can chemically relax stress.”

More information: Peiwen Zheng and Thomas J. McCarthy. “A Surprise from 1954: Siloxane Equilibration Is a Simple, Robust, and Obvious Polymer Self-Healing Mechanism.” Journal of the American Chemical Society. DOI: 10.1021/ja2113257

Journal information: Journal of the American Chemical Society

© 2011 PhysOrg.com