August 30, 2007 feature

New magnetic recording technology uses magneto-electric effect

Magnetic recording is a multi-billion dollar industry and growing, as consumers store more and more data on PCs, laptops, and portable devices. Researchers continue to find new ways to improve the technology, where the current recording density has reached 150 Gb in-2 in commercial products, and 300 Gb in-2 in the newest prototypes.

Most of today’s magnetic recording systems use read heads—sensors that read and write data by hovering over the disk surface—that are based on magneto-resistance effects. When a magnetic field is applied to some materials, they can increase or decrease their electrical resistance. Data can then be stored in the form of electrical signals.

Recently, researchers Marian Vopsaroiu, John Blackburn, and Markys Cain from the National Physical Laboratory in Teddington, UK have proposed a different approach, and discovered some notable improvements. The scientists based their read head design on the magneto-electric (ME) effect instead of the magneto-resistance (MR) effect. This is the first time such a device has been proposed publicly.

ME is often displayed in multiferroic materials—a special class of materials exhibiting multiple ferroic properties (such as ferroelectricity, ferromagnetism, or ferroelasticity). In ME, the electric and magnetic fields are coupled, which facilitates the conversion between energies stored in magnetic and electric fields. This phenomenon is considered to hold promise for a variety of new applications.

“I first had the idea for this application after reading a paper [Shuxiang Dong, Jie-Fang Li, D. Viehland, Appl. Phys. Lett. 83 (2003) 2265] demonstrating experimental results for a laminated tri-layer multiferroic,” Vopsaroiu told PhysOrg.com. He explained that the multiferroic was sensitive enough to detect low (6 x 10-7 Oe) AC magnetic fields at room temperature.

"Knowing that media fields in a recording medium could be as high as 100 Oe, I realized that if you scale down the size of the sensor and apply the same principle, this could function as a read head detector," Vopsaroiu continued. "Initial estimations showed a range of a few microvolts response signal, but more detailed calculations performed with John Blackburn's help revealed better amplitudes close to the millivolts range."

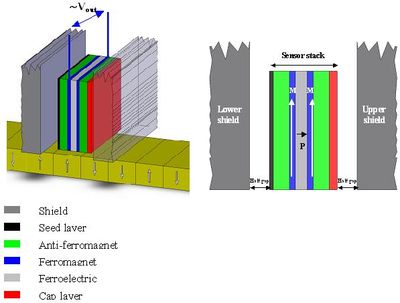

In the read head device, the scientists took advantage of the magnetically induced ME effect, and applied both ac and dc magnetic fields to initiate a change in the electric polarization of the multiferroic material. The actual read head consists of seven layers of materials (compared with 15 in a typical MR head), with a total thickness of about 40 nanometers.

The researchers explain that, as the head moves across the bits on the disk surface, the bits apply the required ac excitation field on the sensor, inducing a response voltage following the same pattern of the bits. The required dc field is more complex, inducing “magnetostriction,” or causing the multiferroic materials in the sensor to change shape under the magnetic field, thus converting magnetic energy into kinetic energy.

“In the ME design, data is stored magnetically on small-magnetized regions known as magnetic memory bits, just as in the case of any recording disk,” Vopsaroiu explained. “The read process is still performed as an electrical signal (i.e. wave function) in a similar way to the operation of the magneto-resistive read heads, but the electrical response is generated in a different way when using an ME read head.”

In ME heads, data is read back directly as induced voltage, whereas MR heads normally require a constant dc test current to measure the change in resistance. This difference gives ME heads the advantage of better thermal performance and reduced power consumption.

Another improvement is the elimination of the need for a horizontal bias field with permanent magnets. Together, these improvements could reduce the cost and time of production by eliminating at least 100 processes from the production line.

Perhaps most significantly, the smaller size of ME heads offers the possibility of increased recording density: the scientists estimate the 40-nm ME heads to achieve a density of 200 Gb in-2, with a resonance frequency of 5.2 GHz. They also predict that the fundamental limits for an ME recording head could enable a thickness down to 5 nm, which could handle recording densities of 1 Tb in-2 and beyond.

Vopsariou said that the group has initiated contact with a magnetic recording head manufacturer on the new reader design and hopes to work on a short feasibility study together. The study would include addressing some of the most controversial issues related to the design, defining limitations, and choosing the best materials.

Citation: Vopsaroiu, Marian, Blackburn, John, Cain, Markys G. “A new magnetic recording read head technology based on the magneto-electric effect.” J. Phys. D: Appl. Phys. 40 (2007) 5027-5033.

Copyright 2007 PhysOrg.com.

All rights reserved. This material may not be published, broadcast, rewritten or redistributed in whole or part without the express written permission of PhysOrg.com.