Engineers 'bone' up on biological materials

In a recent feature article published in Materials Research Society's Bulletin, Dr Michelle Oyen explores the potential uses of synthetic bone-like material. Michelle suggests that these materials will be too expensive to replace materials in typical construction and building applications but can be developed for use in particularly demanding sections of advanced architecture as well as other specialist structural applications.

In addition, the principles involved might be used to make materials that have bone-like qualities without being so obviously directly like bone. Michelle is interested in the general principles found in bone, not just the specific details of collagen-mineral or gelatin-mineral materials.

There is growing interest in materials and systems which imitate nature. Researchers are looking towards nature for inspiration because natural materials are composites, harnessing the best features of several different material types and combining them into a material that is more than the sum of its parts. Biomimetic materials synthesis aims to take the attractive features of a biological system and mimic either the material itself or the process that naturally occurs when the material is made.

Natural bone is of particular interest to researchers because of its unusual combination of mechanical properties: bone is stiff and tough, but it is lightweight.

Bone material

Bone material can be described at four levels of detail:

1. Macroscopic: bone as seen by the naked eye

2. Tissue level: there are two main categories of bone tissue: spongy bone (trabecular bone) which makes up the interior of the bone and compact bone (cortical bone) which forms the surface

3. Cell level: the tissue is made up of cells which are continually being formed and resorped

4. Material (extracellular matrix): a mixture of nonliving material which acts as scaffolding for the bone. This consists of inorganic and organic parts; collagen fibers, ground substance, and bone salts.

Fabricating bone-like material

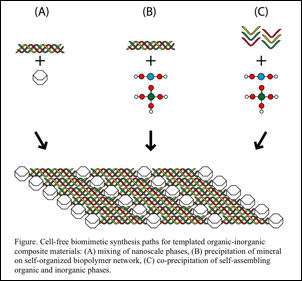

Traditional tissue engineering uses foreign living cells seeded onto an artificial scaffold structure and small molecules, such as growth factor, to create bone-like material. Novel approaches to biomimetic material synthesis can be described as "bottom-up", and emphasize cell-free pathways to create bone-like structures. There are at least three different approaches:

1. The first method involves mixing nanoscale organic and inorganic material to create a composite. Mineral particles are mixed into a string of molecules known as a polymer network. This method is similar to traditional composites technology but here self-assembling biological polymers (collagen) are used. This method creates a simple bone-like material.

2. The second method is to add the components of the mineral phase (rather than formed mineral particles) to the self-assembling biopolymer network. The aim is that the mineral nucleates on specific sites in the network and forms an organised composite on a finer scale.

3. The third method involves mineral formed in situ simultaneous to formation of the biopolymer network. Mineral components are added to monomers, the small molecules that link together to form the biopolymer. The biopolymer and the mineral phase grow together "naturally", creating a material which further resembles bone.

In all three cases the biopolymers autonomously build themselves from the bottom up as the individual components contain enough information to build a template for a structure composed of multiple units. Self-assembling biopolymers reduce the need for energy-intensive processing steps. It is hoped that for all three of the above approaches the self-assembly of the biopolymer will lead to a well-ordered structure with few defects.

Researchers are using biomimetic processing to create a wide variety of bone-like materials. They commonly use collagen and gelatin, but other materials such as silk and synthetic peptides have also been used. Future studies will include multi-component organic matrices with both protein and sugar components.

Applications of bone-like material

Historically, the creation of bone-like materials has been driven by clinical and medical research, emphasising the medical uses for bone replacement. Michelle's research focuses on other possible uses for materials that have bone-like properties, where although the materials information is obtained from natural objects, including biological tissues, the end-applications are industrial.

Bone-like material could push the current limits of architecture, where the ideal material would be very structural with exceptional mechanical properties but also very lightweight. Michelle anticipates that as this "killer combination" is found in bone and other natural materials, we should expect to see biosynthetic materials used in buildings of the future. Michelle explains that "anywhere you have something heavy and brittle, like bricks or concrete, you might be able to use a bone-like material as a replacement where you would need less material (i.e. thinner and lighter sections) but still have excellent mechanical integrity.

Michelle suggests that the first architectural application of bone-like material could be domes or other larger vaulted structures. Further applications appear limitless. With such potential for biosynthetic materials, this interesting area of research is set to become increasingly popular.

Source: University of Cambridge