Better hams with space technology

Space technology is now being used to help Spanish ham experts ensure that hams awarded the highly prized ‘jamon’ label are worthy of the name. Technology used to measure the liquid shift that occurs in an astronaut’s body in microgravity has been developed to measure the water retention in cured hams.

'Jamon', the world-famous Spanish cured ham, is the pride of a culinary nation. As such it is subject to rigid quality control. Highly experienced experts can determine by a mere look, touch and smell whether a cured ham deserves the desired label.

However, the main criteria for a jamon is amount of water in the meat. This is very hard to spot with the naked eye, which makes it a difficult job even for the most experienced inspector.

To solve this problem ESA's technology transfer broker Inasmet helped Spanish ham producer Esteban Espuna to adapt technology first developed for space by Spanish engineering company NTE. The technology was designed to monitor the fluid shift that occurs in an astronaut's body during spaceflight.

Developed in the framework of ESA's Technology Research Programme, NTE created Spectroscopy of Electrical Impedance for medical purposes. The instrument minutely monitors and measures the upward drift of body liquids experienced by astronauts in microgravity by applying a low electrical current to the astronaut's body and analyzing its exit.

This technology has now been redeveloped and tailored to measure the water retention level in the famous Spanish hams.

To be labelled 'cured', a ham has to meet specific criteria of water retention after several months of curing. The hams can neither be too dry nor too ‘wet’ as this would diminish the quality.

To make sure that a cured ham is really a 'jamon', the so-called PSE (pale, soft and exudative) hams need to be weeded out before they hit the market and dilute the quality brand of Spanish ham.

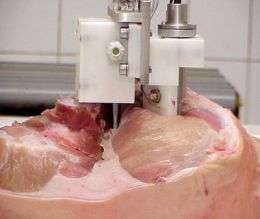

A detection tool to measure the level of water retention in the hams is now integrated in the production line of Spanish ham producer Esteban Espuna. Hams that do not comply with the specified quality parameters are automatically removed from the line and can then be used to produce boiled hams.

By improving the speed and efficiency of detecting hams that do not meet the high quality standards, the brand name of Esteban Espuna’s products is strengthened and the client receives a better quality product at a lower price.

By applying this space-derived technology to ham production, Esteban Espuna has increased its profits at a rate of 3% a year and is helping to guarantee the excellence of ‘jamon’.

Provided by ESA