April 20, 2009 weblog

Unzipping Carbon Nanotubes Can Make Graphene Ribbons

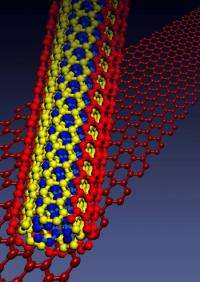

(PhysOrg.com) -- By "unzipping" carbon nanotubes, researchers have shown how to make flat graphene ribbons. Graphene, which is a one-atom-thick sheet of carbon that looks like chicken wire, has unique electrical properties that could have many future electronics applications. However, one of the biggest challenges researchers currently face is producing graphene in large quantities.

Recently, two research groups have demonstrated that unzipping carbon nanotubes can produce graphene ribbons in a variety of widths.

In the first group, scientists at Rice University in Houston led by James Tour used sulphuric acid and an oxidizing agent to chemically create a hole in the carbon nanotubes. The hole expanded along the side of the nanotube, unzipping the tube to form a flat graphene ribbon. The width of the graphene ribbon depended on the diameter of the nanotubes. In their experiments, the researchers used multiwalled nanotubes with diameters ranging from 40 to 80 nanometers, resulting in ribbons with widths from 100 to 250 nanometers, and about 4 micrometers long.

The researchers suggest that this type of graphene ribbon could be used for conductive or semiconducting thin films, and possibly as an inexpensive substitute for monocrystalline silicon in photovoltaics. However, the method makes it difficult to accurately place a single ribbon on a substrate, which will make it challenging to fabricate many devices.

The second group, which consisted of Stanford researchers led by Hongiie Dai, tried a different approach. They placed nanotubes on a silicon substrate, coated them with a polymer, and baked them. Then they peeled off the polymer, which the nanotubes were embedded in. Exposing this polymer-nanotube material to a 10-watt argon plasma for 10 seconds cut some of the exposed nanotubes into graphene ribbons. Longer exposures could cut nanotubes that were further embedded in the polymer. After dissolving the polymer, only the graphene ribbons remained. This baking and cutting method produced graphene ribbons with relatively clean edges and few defects, which optimizes their conductive properties.

While both methods provide new ways of producing graphene, more work needs to be done to achieve better control of the widths, edges, and uniformity. Finding a practical way to form graphene is necessary for many future applications, including high-speed transistors, sensors, and even scaffolding for tissue regeneration.

© 2009 PhysOrg.com