Biodegradable synthetic resin replaces vital body parts

Researchers at the University of Twente (UT) have developed a new type of resin that can be broken down by the body. This new resin makes it possible to replicate important body parts exactly and make them fit precisely.

The resin can be given different properties depending on where in the body it is to be used. Cells can be sown and cultured on these models, so that the tissues grown are, in fact, produced by the body itself. The new resin has been developed by Ferry Melchels and Prof. Dirk Grijpma of the UT’s Polymer Chemistry and Biomaterials research group. An article on this breakthrough will be appearing in the authoritative specialist journal, Biomaterials.

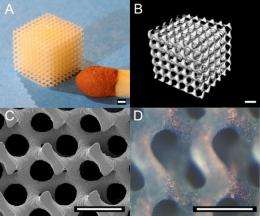

Stereolithography is a technology with which three-dimensional objects can be made from a digital design. It is also possible to scan an object using a CT scanner (or micro-CT scanner) to obtain a digital image. The object in question can subsequently be copied extremely accurately with a stereolithograph. A stereolithograph is therefore a 3D replicating machine with a very high resolution. The way it works is based on the local hardening of a liquid resin with computer-driven light. The resins available for stereolithography so far harden into chemical networks that cannot be broken down.

Resin

For the first time, researchers from the UT have developed a biodegradable resin that can be used for this replicating machine. They have made the resin in such a way that it can be broken down by the body. Making objects from this resin may have great advantages for a many medical applications. If, for example, a child has a heart valve disorder, a 3D digital image of the heart valve can be created using a CT scanner. The model in the stereolithograph can be copied exactly with the new resin. If the structure is made porous, the child’s own cells can be placed on it. This porosity also gives nutrients access to the cells. Ultimately, after the carrier structure has broken down, only the natural tissue remains. Another possibility is to use the resin to create structures for correcting skull defects. You can fabricate a shape very accurately using a stereolithograph. By growing the patient’s own cells on it, his or her own natural bone tissue will be regenerated.

Source: the University of Twente