Dual simulation improves crash performance

Crash tests often produce startling results. A new simulation process which factors in deformation during production as well as preliminary damage can predict the results of a crash test more accurately than ever.

There are components that save lives: if a car rolls over during an accident, the ‘B-pillar’ plays a key role. It forms one of the connections between the floor and roof of the vehicle and is designed to prevent the passenger cell from deforming too much. The materials from which the B-pillar is manufactured therefore need to meet very exacting requirements: to save fuel they need to be ultra-lightweight, yet at the same time need to be tremendously strong and must not break. Yet what does the optimum component actually look like? With the aid of countless experiments, simulations and crash tests, the auto industry has been getting nearer to answering this question. Now Fraunhofer researchers are providing further impetus to development.

Engineers will usually carry out a range of virtual tests. Known materials properties provide the basic knowledge in such a scenario. “We are well aware of the physical and mechanical characteristics of the materials in their original state,” says Dr. Dong-Zhi Sun, Group leader at the Fraunhofer Institute for Mechanics of Materials IWM. Yet during the course of the manufacturing process, the components change: with a B-pillar, for instance, the material goes through a complicated manufacturing chain. As it is deformed and stretched, minor damage such as pore formation may occur.

“If you're going to fit these kinds of parts into vehicles, you need to take into account their deformation history during manufacture,” explains Sun. That's why the researchers have developed a special method: “With our failure model, we can simulate manufacturing processes more effectively,” explains Sun.

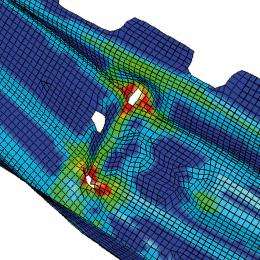

“To ensure we understand the manufacturing processes inside out, we work together closely with automakers and materials producers.” Thanks to the simulation, the researchers can precisely model and analyze the deformation of the component during manufacture. So they know to what extent the process affects the properties of the end product, and whether the manufacturing process gives rise to potential preliminary damage such as pore formation and microcracks. The engineers combine the results of the process simulation with a crash simulation, which is conducted using a newly developed material model.

The new method enables components with optimum properties and improved crash performance to be developed. “Unlike conventional crash simulations, we can predict far more accurately how extensively the component will deform during the crash before it fails,” says Sun.

Source: Fraunhofer-Gesellschaft (news : web)