Space technology optimises windmill efficiency

(PhysOrg.com) -- A French start-up company from ESA's Business Incubation Centre in the Netherlands has developed a small instrument to measure wind speed and direction from the ground up to heights of 200 metres -- information that is vital when deciding where to build a wind turbine to produce electricity.

A French start-up company from ESA’s Business Incubation Centre in the Netherlands has developed a small instrument to measure wind speed and direction from the ground up to heights of 200 metres - information that is vital when deciding where to build a wind turbine to produce electricity.

The French company Leosphere developed their system Windcube using ‘lidar’ (light detection and ranging) remote-sensing technology to measure wind speed and direction, turbulence and wind shear with great precision. Using a laser beam to measure the distance to objects is similar to how sonar measures distances underwater using sound pulses.

The lidar concept being used by Leosphere is similar to that ESA will use on its Aeolus Earth Explorer Atmospheric Dynamics Mission, to provide global observations of wind profiles from space to improve the quality of weather forecasts, and to advance our understanding of atmospheric dynamics and climate processes. Aeolus is planned for launch in 2011.

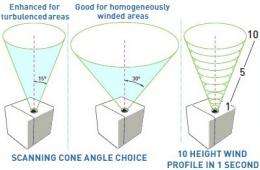

“Windcube sends laser pulses to measure wind characteristics. The laser light is scattered on its path by particles in the air, such as dust, water and aerosols, and bounced back to an optical sensor. These signals capture the movement in atmosphere particles and by mathematical calculations we can determine the absolute wind speed and direction in the laser pulse’s line of sight,” explains Laurent Sauvage, Leosphere Scientific Director.

Kick-started by ESA BIC’s business support

Leosphere was supported during its start-up phase by ESA’s Business Incubation Centre (BIC) in Noordwijk, the Netherlands. The company also collaborated with the French ONERA aerospace laboratory during development.

“We were supported by ESA experts to refine our business plan and they helped us with our system development. Actually, thanks to the strong support we received at ESTEC, and the excellent information provided by ESA’s lidar experts with their unique experience operating equipment in severe environmental conditions, we have been able to develop our business throughout Europe,” says Laurent Sauvage.

ESA gave the technology development a major push though its business incubation initiative. Errico Armandillo, head of the Opto-Electronic Section at ESA, explained: “Our expertise from Aeolus turned out to be highly relevant for Leosphere’s engineers in designing a system to best resist temperature variations, to optimise its weight and to define the best coating for the optics. Knowhow from ESA engineers on working in hostile space environments turned out to be very useful for them.”

Don’t raise mast, send the light

If new wind farms are to be profitable, it is essential to know the local wind conditions and to identify the best position for each wind turbine. Understanding the wind conditions can be difficult because trees, cliffs or hills affect the strength and direction. A typical method is to raise masts and then estimate wind conditions. The Windcube can replace or complement this method.

Klaus Andersen from Alpha Wind Energy, Denmark, says: “The Windcube fulfils our requirement to do accurate wind measurement in remote locations where a conventional mast is not feasible for various reasons. Leosphere has made it possible for Alpha Wind Energy to move into a new technology, which will make wind measurements possible in places previously inaccessible.”

Same technology now also in other fields

Leosphere has designed several portable lidar systems for the environmental market, following the business plan developed and validated at the ESA BIC in Noordwijk.

“With our Windcube system we can measure the wind profile at ten programmable measurement heights in the range of either 40-200 m or 100-5000 m vertically above the point of measurement, depending on the needs of our customers. In addition, we have developed other systems using the same lidar technology to measure clouds and aerosol parameters. More than 80 systems are now installed in 14 countries, contributing to regional and global monitoring of meteorological and climate change processes,” added Laurent Sauvage.

Considered to be an emerging technology just a few years ago, the wind and aerosol lidar technology is now widely used for routine observation instruments feeding meteorological databases and models.

Provided by ESA