January 14, 2010 report

Self-assembling solar panels a step closer

(PhysOrg.com) -- Scientists Robert J. Knuesel and Heiko O. Jacobs of the University of Minnesota have developed a way to make tiny solar cells self-assemble.

The researchers had previously been unsuccessful in their attempts to make self-assembling electronic components. In large systems gravity can be used to drive self-assembly, and in nanoscale systems chemical processes can be used, but between the two scales, in the micrometer range, it is much more difficult.

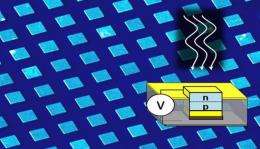

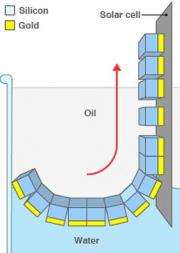

To overcome the difficulties, Kneusel and Jacobs designed a flexible substrate of a thin layer of copper covered with propylene-terephthalate (PET). Regular depressions the same size as the "chiplets" were etched into the PET layer and then the sheet was dipped into a bath of molten solder, which coated the exposed copper in the etched depressions. Each chiplet consisted of a 20-60 µm silicon cube with one gold face. The silicon sides had a coating of hydrophobic (water-repelling) molecules, while the gold side had a hydrophilic (water-attracting) coating.

When the elements were placed in a container containing oil and water, they neatly arranged themselves in a sheet at the boundary between the liquids, with the gold side pointed down to the water layer. The substrate was then pulled slowly up through the boundary like a conveyor belt, and the elements neatly dropped in place in the depressions as the solder attracted the gold side. Accuracy was 98%. The assembly was covered with epoxy to keep the chiplets in place, and then a conducting electrode layer was added.

The device was able to assemble 62,000 elements, each of them thinner than a human hair, in only three minutes. The elimination of a dependency on gravity and sedimentation meant the chiplets could be reduced to below 100 micrometers in size. It was important to limit the assembly time to avoid oxidation of the surfaces, which would reduce surface energies and interfere with self-assembly. The water layer had to be acidic, at pH 2.0, and the temperature had to be kept at 95C to keep the solder molten.

The researchers think they can adapt their method to smaller components and larger assembled devices, and it could be used to cheaply and quickly assemble all kinds of high-quality electronic components on a wide range of flexible or inflexible substrates including plastics, semiconductors and metals. The assemblages could find uses in numerous applications such as solar cells, video displays and tiny semiconductors.

The use of this method in solar cell production would reduce the cost considerably since less silicon is needed, and it should also be possible to assemble solar chiplets into transparent, flexible materials, which would extend their range of uses.

The paper is published in the Proceedings of the National Academy of Sciences (PNAS).

More information: Self-assembly of microscopic chiplets at a liquid-liquid-solid interface forming a flexible segmented monocrystalline solar cell, Robert J. Knuesel and Heiko O. Jacobs, PNAS, DOI:10.1073/pnas.0909482107

© 2010 PhysOrg.com