September 9, 2005 feature

Nanotechnology for Recovery and Reuse of Spilled Oil

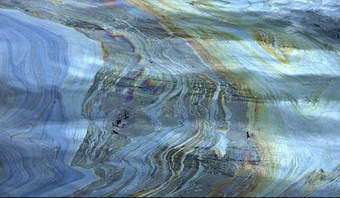

The recent hurricane Katrina disaster has resulted in an oil crisis. Apart from the shortage there are reports of oil spills. Interface Science Corporation has announced that the company is launching its proprietary oil remediation and recovery application. They hare utilizing nanotechnology for this purpose.

The use of treated material absorbs about 40 times it weight in oil, far exceeding existing commercially available remediation materials. Because water is completely rejected by the ISC material, the oil can be recovered for use, a substantial benefit in oil spill cleanup efforts. The new oil cleanup solution uses patented Self-Assembled Monolayer (SAMs) technology. The technology recently was announced and is of extreme importance. This highly effective material shall help mitigate the environmental and health impacts caused by the approximate 3,000 worldwide annual oil spills.

The announcement of this innovation comes about six months ahead of the company's original planned. The technology emphasizes materials and surface innovation at the nanoscale. The use of self-assembly occurs abundantly in nature even within our own bodies. Different molecules within the body result in the formation of a wide variety of microstructures. Interface Sciences Corporation has, through the use of its patented technology and patented application methods, synthetically recreated Mother Nature's ability to create self-assembled monolayers (SAMs) up to several layers thick depending on the application.

The marriage of nanoparticulates and SAMs provides direct access to a new class of nanostructured hybrid materials that are very useful as environmental sorbent materials, structural components, coatings, wetting control, friction and lubrication control, adhesion, bio-related applications (e.g. pharmaceutical controlled release, and biomedical implant materials), sensing/detection, environmental remediation and electronics materials.

Inherent in the usefulness of the SAMs system is the ability to form chemical foundations from which other building blocks can be used to form more complex structures. It has been shown that by designing the interfacial chemistry that is capable of being engaged with specific polymer systems, a designed interface can enhance the adhesion properties of a polymer to a solid substrate. The same foundation can be laid with a specific chemical foundation for chemical anchoring or polymer cross-linking initialization. The chemical foundation can be controlled with mixtures of SAM molecule lengths and functionalities for further diversity in application.

This technology is a path-breaking one and is poised to be a watershed in the oil spills recovery and remediation process. Apart from being eco-protective, it is also useful as most of the spilled oil is recovered.

Dr. Bikram Lamba, an international management consultant, is Chairman & Managing Director of Tormacon Limited- a multi-disciplinary consultancy organization. He can be contacted at 905 848 4205. email: torconsult@rogers.com, www.torconsult.com

Copyright 2005 PhysOrg.com